With environmental protection sweeping the globe, governments are paying more attention to limiting plastics and using recycled materials than ever before. The textile and clothing industry was the first to try to make recycled fabrics with recycled materials. What is the recycled fabric?

Under the dual carbon target, the textile and garment industry, as a major carbon emitter, cannot escape the process of transformation and evolution. It is believed that in the future, energy conservation, environmental protection, and carbon emission reduction will become a new social hot spot, and “recycled textiles” will become one of the mainstream trends of relevant industries, just like recycled paper and recycled plastics.

What is the recycled fabric?

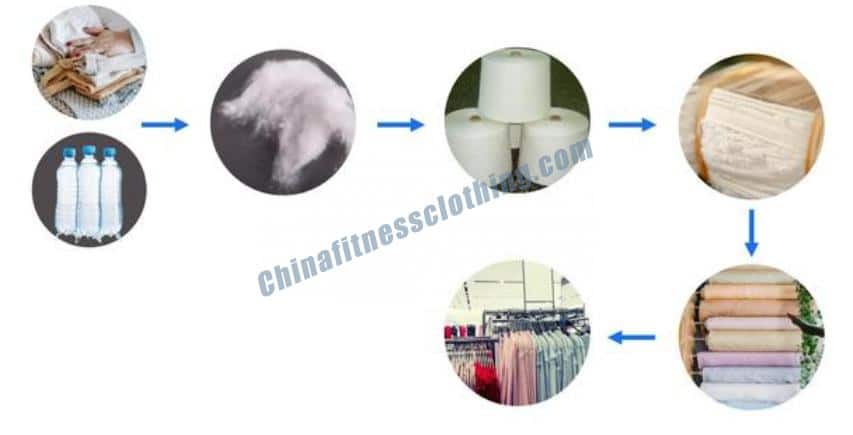

Recycled fabric is the waste fabric after washing and processing again to revitalize, become the fabric can be used and sold again. Of course, many processes are needed in this process. Recycled fabric is evolved by means of technology through various materials, which is the power of environmental protection and is also caused by technological precipitation.

Textiles made from natural or synthetic fibers are not only used in clothing but also in homes, hospitals, workplaces, vehicles, in the form of cleaning materials, as leisure equipment or protective clothing, etc. If these textiles are sorted, graded, and reused to make fabrics for different end uses, they are called recycled textiles.

Why use recycled fabric:

Recycled fabrics have a bright future

The development of recycled environment-friendly fabrics is of great significance to resource conservation and environment protection. According to authoritative statistics, recycling 1 ton of waste textile is equal to reducing carbon dioxide emissions by 3.2 tons. Compared with landfills or incineration, it can save land resources, protect the environment and reduce the consumption of crude oil resources.

Once in a landfill, natural fibers can take weeks to years to decompose. They can release methane and carbon dioxide gases into the atmosphere. In addition, synthetic textiles are designed not to decompose. In landfills, they can release toxic substances into groundwater and the surrounding soil.

Therefore, to reduce emissions, the development of recycled environmentally friendly fabrics is a very important means.

GRS recycled fabrics become the big trend

The so-called GRS certificate is the global textile and garment recycling standard set by Control Union. In addition to regulating the source of raw materials, the verification standards also regulate the treatment of wastewater and the use of chemicals in the production process.

As recycled fabrics are now popular, EU member states have turned their attention to recycled fabrics, bringing a large number of inquiries and orders for recycled fabrics to the market. Fast-fashion brand Zara, for example, recently announced its sustainable fashion goals. By 2025, 100 percent of the products of all of the group’s brands, including Zara, Pull & Bear and Massimo Dutti, will be made from recycled fabrics.

BURBERRY has announced a full use of recycled, biodegradable materials by 2025!

Adidas announces full use of recycled polyester by 2024!

Zara has announced plans to fully use recycled and sustainable materials by 2025!

H&M has announced a move to 100% recycled materials by 2030!

Benefits of recycled fabric

- Reduce dependence on raw petroleum as a raw material

- Reducing space requirements for landfills and disposal costs for governments

- Reduce greenhouse gas emissions. With the reuse of recycled fabrics during the manufacturing process or consumption cycle, carbon dioxide emissions are greatly reduced compared to the production of original materials

- Slowdown global warming

- Avoid using raw fibers

- Reduces pressure on new resources

- Reduce energy and water consumption

- Avoid contamination

- Reduce the need for dyes and fixative

- Provide environmental and economic benefits

- Save energy and reduce pollution

- Protect the planet for the next generation