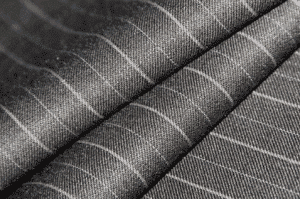

What Is TR Fabric?

The tr fabric is a blended fabric, which is made by blending two materials, rayon and polyester, in a certain proportion (polyester accounts for more than 60%). This blended fabric can combine the characteristics of both fabrics. When the polyester is not less than 50%, this blended fabric can maintain the characteristics of polyester’s firmness, wrinkle resistance, dimensional stability, and strong washability and wearability. The mixing of viscose fiber improves the air permeability of the fabric and improves the resistance to pores; it reduces the pilling and antistatic phenomenon of the fabric.

In order to let you have a better understanding of this fabric, here, I would like to share the advantages and disadvantages of tr fabric. For more information, you can also visit CHINAFITNESSCLOTHING.

Features of TR Fabric

The polyester/viscose blended ratio is mostly 65/35 or 67/33. The characteristics of this type of blended fabric are smooth and clean texture, bright color, strong wool style, good elasticity, and good moisture absorption; but the iron-free property is poor.

Advantages of TR Fabric

(1) High strength: short fiber strength is 2.6~5.7Cn/dtex, high-strength fiber is 5.6~8.0Cn/dtex. Due to low moisture absorption, its wet strength and dry strength are basically the same, and the impact strength is 4 times higher than Nylon and 20 times higher than viscose fiber.

(2) Good elasticity: The elasticity is close to that of wool. When it is stretched by 5% to 6%, it can almost completely recover. The wrinkle resistance exceeds other fibers, that is, the fabric is not wrinkled and has good dimensional stability. Its elastic modulus is 22~141cN/dtex, which is 2~3 times higher than nylon.

(3) Good water absorption.

(4) Good abrasion resistance: its abrasion resistance is second only to nylon with the best abrasion resistance, better than other natural fibers and synthetic fibers.

(5) Good light resistance: light resistance is second only to acrylic fiber.

(6) Corrosion resistance: resistant to bleaching agents, oxidants, ketones, ketones, petroleum products and inorganic acids; it is resistant to dilute alkali and not afraid of mildew, but hot alkali can make it decompose.

These advantages enable tr fabrics to replace expensive wool fabrics and at the same time facilitate cutting and shaping. Therefore, tr fabrics are often used to make suits, trousers, autumn and winter coats, etc.

Disadvantages of TR Fabric

This kind of fabric has no major disadvantages, but its feel and touch are not as good as pure cotton. Clothes made of tr fabric are not as comfortable as pure cotton clothes.

Difference Between TR Fabric And Polyester Fabric

Polyester: good pleating effect, not easy to deform, and poor hand feeling. In short, it means that the shape is good and the hand feeling is bad.

TR fabric is more skin-friendly, but due to the composition of the fabric, it will fold over time.

Currently, on the market, tr refers to a 30% cotton + 70% polyester fabric. The advantage is that it is comfortable and soft to wear. The disadvantage is that the pleats are easy to loose, easy to pilling, and difficult to care for.

Polyester refers to 100% polyester fabric. The advantage is that the pleats are sharp and will not be scattered. The shape is very good, anti-wrinkle, anti-pilling, and easy to care for. The disadvantage is that it has a bad feeling and is not suitable for people with very sensitive skin.