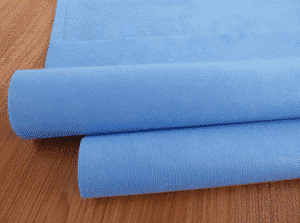

Where are the six major non-woven fabric production bases in China? Some products such as face masks, non-woven disposable underwear are both made with this material. The mask we usually say is a non-woven material. How about the production of masks in China?

Six Major Non-woven Fabric Production Bases in China

- Changyuan City, Henan Province

Changyuan City, Henan Province, ranks first in China’s Sanwei Material Base. It has more than 70 sanitary materials companies and more than 2,000 operating companies. It usually accounts for more than 50% of the national market sales.

- Xiantao City, Hubei Province

China’s non-woven fabric capital: Xiantao City, Hubei Province has 1,011 non-woven fabric and product enterprises, of which 103 are above designated size and employ more than 100,000 employees. It accounts for 60% of the non-woven product market in China.

- Shaoxing City, Zhejiang Province

- Zibo City, Shandong Province

- Yizheng City, Jiangsu Province

Famous Town of Nonwovens and Chemical Fibers in China: Zhenzhou Town, Yizheng City, Jiangsu Province.

- Nanhai District, Guangdong Province

China’s medical and health nonwoven products demonstration base. The demonstration base is located in Jiujiang Town, Nanhai District, with a total planned area of about 3.32 million square meters. The northern part is divided into four areas: material production area, finished product production area, high-end industrial area and logistics warehouse distribution area. The medical and health non-woven fabric demonstration base will be built into an industrial gathering base with an annual output value of more than 20 billion yuan.

Masks and Non-woven Fabric

We usually say that masks are non-woven materials. Non-woven fabrics are non-woven fabrics compared to woven fabrics. They are composed of oriented or random fibers.

From the point of view of mask materials, polypropylene high-melt index non-woven fabrics have become the best choice, which can be used in many aspects such as disposable surgical gowns, sheets, masks, drapes, and liquid absorbent pads.

Reported data shows that 1 ton of high melting index fiber material can produce about 250,000 germ protection masks, and 1 ton of transparent material can produce about 500,000 medical disposable syringes. In the face of the epidemic, polypropylene manufacturers are taking active actions to ensure raw materials. Can be adequately supplied.

China’s Mask Production

China’s masks have already achieved assembly line production, with a high degree of intelligence. The production of masks is very fast, and it is not a labor-intensive enterprise.

Under normal circumstances, one machine can produce 2 to 3 masks per second. Usually, the production quantity per minute is hundreds of masks. Multiple production lines can produce at the speed of the ejection chamber.

Under the previous normal production capacity, domestic mask companies were not moisturized, and even seriously surplus. In recent years, mask companies have experienced many twists and turns. Before SARS in 2003, there were not many mask manufacturers. During and after SARS, there was a round of blowouts. Later, some companies appeared in Beijing smog. Now the smog is not so serious, and some Mask companies have been eliminated, and this industry is also market-oriented.

Even so, China’s mask production still accounts for 50% of the world. Mask companies are mainly located in the Yangtze River Delta, the Pearl River Delta, Hubei Xiantao and Anhui Tongcheng. There are at least 30,000 mask companies in the country, including more than 20 well-known mask companies. Hubei Xiantao has about 3,000 mask companies, which is an industrial cluster. However, more than 95% of Xiantao mask companies are export companies. They are produced in small family workshops. One household has one factory.