Cationic polyester is short for cationic dyeable polyester, it is abbreviated as PBT, and some factories are also refer to it as CD. It is a kind of modified polyester fiber, and also a type of dyeable polyester fiber, which can be dyed with cationic dyes at a temperature above 110 degrees. Cationic polyester is essentially an ordinary polyester macromolecule with a small cationic dye reaction link.

Cationic yarn and cationic yarns are used in the production of cationic fabrics, often in the warp direction, while the weft direction typically uses polyester yarns, which contributes to the two-color effect in yarn dyed fabrics cationic.

Since cationic polyester will react with cationic dye in the dyeing process, the color fastness of dyed fabric is higher than that of ordinary polyester. Cationic fabrics can be compared to cellulose and protein fabrics, such as those made from natural cellulose, protein fabrics, cotton fiber, and pure cotton fabrics, but differ in light fastness and washing and light fastness.

These fibers can be colored with disperse dyes. Compared to ionic dyes, distribute dyes have smaller-sized molecular termination coefficients and lower accumulation residential or commercial properties, so these dyes can not provide deep and brilliant colors. Cationic fabric feels soft and comfortable, and cationic nylon yarn is often used to enhance durability and color brilliance.

This type of fibers was born likewise to reduce the Tg (glass shift temperature level) of the polymer, 10 ° C lower than typical Polyester fibers, so to get more segmental movement and open polymer structure. Resulting in an increased rate of diffusion of the color in the fiber at a lower temperature level. Cationic fabrics exhibit bleach resistance, dilute alkali resistance bleach, and resistance to inorganic acids, petroleum products, and hydrocarbons ketones petroleum products, making them suitable for environments where exposure to petroleum products and inorganic acids occurs.

Such fabrics can replace more expensive materials, thereby reducing the cost for manufacturers.

Cationic dyeable polyester vs polyester- 7 differences

When comparing cationic dyeable polyester to regular polyester, several key differences highlight why cationic fabrics are increasingly favored in the textile industry, especially for sportswear fabrics, warm clothing, and high-end underwear.

- Two-Color Effect: Cationic dyeable polyester enables the creation of two color fabrics through yarn-dyed weaving, thanks to its unique ability to absorb cationic dyes. Regular polyester lacks this feature, limiting its design possibilities.

- Modified Fiber Structure: Cationic dyeable polyester is engineered by modifying polyester fibers to introduce cationic sites, which interact with cationic dyes. In contrast, regular polyester is unmodified, resulting in different dyeing properties and less vibrant color options.

- Superior Chemical Properties: Cationic dyeable polyester stands out for its corrosion resistance and dilute alkali resistance, making it more durable in challenging environments. Regular polyester does not offer the same level of protection against chemicals and alkalis.

- Dyeing Process Sensitivity: The dyeing process for cationic dyeable polyester requires careful temperature control to ensure color consistency and stability, as the fiber is more sensitive to temperature changes. Regular polyester is less sensitive, but this can result in less precise color outcomes.

- Enhanced Physical Properties: Cationic dyeable polyester offers excellent UV resistance and abrasion resistance, making it ideal for activewear and outdoor applications. Regular polyester may not provide the same level of protection or durability.

- Compatibility with Artificial Fibers: Cationic dyeable polyester is particularly suitable for blending with artificial fibers such as polyester and nylon, enhancing the strength, elasticity, and performance of the final fabric. Regular polyester may not be as versatile in these applications.

- Wider Color Range: Thanks to its ability to absorb cationic dyes, cationic dyeable polyester can achieve a broader spectrum of vibrant colors, making it a popular choice for fashion-forward and functional textiles. Regular polyester is more limited in its color options, which can restrict design creativity.

These differences make cationic dyeable polyester a preferred material for manufacturers seeking fabrics with advanced chemical and physical properties, a wide range of color possibilities, and the ability to create innovative, high-performance garments.

Application Of Cationic Fabric

-

- The cationic fabric has very good water absorption and its dyeing tank difference is relatively small, so it is especially suitable for sports clothes. It is mainly made into interlock fabrics, sweatshirts, compression garments, sweatpants, yoga clothes, fitness apparel, etc. If the cation fabric is thicker and the brushing effect is very good, it can be made into warm clothes, warm pants, etc.

- The cationic polyester/spandex jersey is also very environmentally friendly and can be used as an environmentally friendly polyester/spandex fabric.

- The cation fabric feels soft and comfortable to wear. At the same time, the color is bright, the effect is similar to natural fabrics, and it has good elasticity and hygienic properties. Therefore, the fabric can be used to make high-end underwear, swimwear and sportswear and other popular cationic cloth.

Why cationic dyeable polyester is darker than ordinary polyester under the same dyeing condition?

- Cationic polyester can be dyed with cationic dyes, while ordinary polyester not.

- Under the same dyeing conditions, the cationic coloring temperature is lower than that of ordinary polyester, because it has a longer dyeing time.

- Cationic polyester has a lower crystallinity than regular polyester because it is easier to paint.

Two-Tone Effect of Cationic Dyed Polyester Fabric

5 Benefits of cationic polyester

-

- At 120 ~ 125 ℃, the fabric can go with the cationic dye dyeing level; Polyester must be dyed with disperse dye at 130~135 ℃. Therefore, two kinds of polyester come into being in the formation of two-color fabric (with the exception of medium and light colors).

- Due to the great water-absorbing, cationic dyed polyester is suitable for the production of fitness apparel, sportswear, undergarments, etc.

- In environmental protection, cationic polyester ammonia cloth is widely used, it can be used as environmental polyester fabric.

- The cationic fabric has high wear resistance. The fabrics mixed with cationic polyester, ordinary polyester, spandex, or other artificial fiber fabric, have much higher strength, and better elasticity. Their wear resistance of them is second only to nylon.

- Cationic polyester fabrics have some chemical properties, such as corrosion resistance, dilute alkali resistance, and bleaching resistance, as well as some physical properties, such as the ability to resist ultraviolet light.

Disadvantages Of Cationic Fabric

There are basically no shortcomings in cationic fabrics, but the production cost is higher than 100% polyester fabrics, and it is easy to be replaced by yarn-dyed fabrics.

Price Of Cationic Fabric

The price of cation fabrics with different parameters varies greatly. The wholesale price of this fabric ranges from more than ten yuan to more than thirty yuan. Therefore, you should ask the sales staff about the price before placing an order.

Dyeing Advantages of Cationic Dyed Polyester

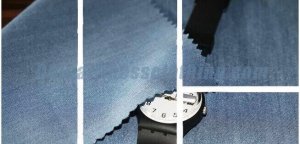

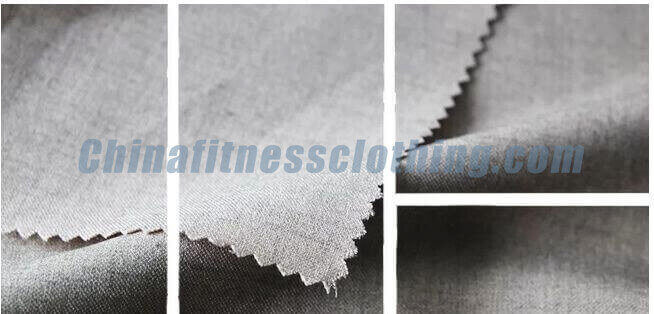

Cationic modified polyester filament is a new type of polyester product spun by introducing dimethyl isophthalate with polar group SO3Na into polyester chips. Its appearance is no different from that of ordinary polyester filament. However, the adoption of ionic modification, not only greatly improves the fiber’s color absorption performance, but also reduces the crystallinity, making dye molecules easy to penetrate, making the fiber easy to dye, and increasing the color absorption rate and improving the hygroscopicity.

This kind of fiber not only ensures that cations are easy to dye but also increases the micropores of the fiber and improve the dye uptake, air permeability, and hygroscopicity of the fiber, thus further adapting to the simulated filamentation of polyester fiber; Through silk simulation, the fabric can be soft, breathable, comfortable, antistatic and dyeable at normal temperature and pressure. Cation-modified multifunctional wool-like fabric can make the fabric soft to the touch, anti-static, anti-pilling, and co-dyeing with wool at normal temperature and pressure.

The fabric woven with modified cationic polyester fiber has the following characteristics when dyed with cationic dyes:

- Bright color and good deep dyeing;

- High exhaustion rate (high dye uptake rate);

- Good fastness to sunlight and smoke fading;

- Good dye compatibility during color matching dyeing;

- Good stability in high-temperature dyeing bath;

- The contamination to other fibers including ordinary polyester fiber is small;

- The diffusion rate into the fiber is fast, and there is no ring dyeing phenomenon;

- When the pH value changes in the dyeing bath, the dye has high stability. The fabric is comparable to natural fabrics in terms of wearing comfort, dyeing vividness, etc., and lower in price than natural silk, which can produce high added value.

Development prospect of cationic polyester

With the improvement of people’s consumption level and the popularization of textile knowledge, people will pay more attention to the experience and responsibility of products in the future. For example, whether the product is environmental protection, whether it is comfortable, or whether it can bring a sense of existence to their hearts.

Cationic polyester has a very good prospect in the field of fitness clothing and underwear production. Our R&D department will invest energy and money to develop and customize more functional cationic products for worldwide customers.