In my 10+ years in the sportswear manufacturing trenches, I’ve watched the humble polo shirt evolve. It has transformed from a stiff corporate uniform into a highly technical piece of engineering within the fashion industry. Today, sourcing high quality polo shirts is no longer just about sewing a collar onto a tee; it’s about breathable micro-structures, moisture-wicking polymers, and cuts that bridge the gap between the boardroom and the golf course.

As we move deeper into 2026, the demand for custom polo shirts is skyrocketing. Whether for corporate branding, golf clubs, or retail fashion lines, finding trusted polo shirt manufacturers is the single most critical step for your business. But here is the hard truth: not all clothing manufacturers can handle the complexity of modern performance polos.

This guide isn’t just a list; it is a comprehensive resource for bulk orders. We will analyze the top 10 polo shirt manufacturers globally, dissect the manufacturing process, and equip you with the technical knowledge to distinguish a “Class A” facility from a garage workshop.

Part 1: The Global Top 10 Polo Shirt Manufacturers (2026 Edition)

We have curated this list of leading manufacturers based on updated 2026 production capacity, technical capability (Cut & Sew vs. Seamless), and strict quality control standards.

1. Maes Group (ChinaFitnessClothing)

Location: Haining/Hangzhou, China

Let’s be transparent: This is us. But I am not listing us first just because I’m writing this. I’m listing us because, entering our 29th year as premier apparel manufacturers, we have pivoted from general manufacturing to become a High-end Cut & Sew Manufacturer.

Unlike mass-market “seamless” factories, our engineering-grade facility focuses on structure, fit, and complex fabric compositions essential for high quality polo shirts. We are not just a factory; we are a partner for brands that demand retail-ready precision.

-

Website: chinafitnessclothing.com

-

Core Competency: Engineering-grade Cut & Sew Activewear & Polos.

-

Fabric Expertise: Recycled Poly (rPET), Spandex Blends, Bamboo Charcoal, Pique Mesh (180-280 GSM).

Why We Are a Top Choice for Custom Polo Shirts

Technical R&D: We possess an in-house fabric lab to test color fastness (Level 4+) and shrinkage rates, ensuring your custom polo shirts last for years.

Flexible Production: We support startups with a low minimum order quantity (starting at 100 pieces), while retaining the capacity for massive bulk production for established chains.

Our Manufacturing Services

-

Private Label: Full branding services including heat-sealed neck labels and sustainable packaging.

-

Decoration: Expert custom embroidery and screen printing.

-

Inventory: 12,000+ blank units ready for rapid prototyping.

Considerations:

-

Not the Cheapest: We compete on quality. If you want a $3 polo, other clothing manufacturers might suit you better.

-

Logistics: Based in China means shipping times to the US/EU range from 7-10 days via air express.

2. MELENGO

Location: Los Angeles, USA / Global Network

Melengo acts as a bridge between Western design concepts and global manufacturing. As they mature in the market, they remain a platform-based solution ideal for brands that need hand-holding through the polo shirt designs phase.

-

Website: melengo.com

-

Main Products: Hoodies, T-Shirts, Polos.

Key Features

US Headquartered: Easier communication for American clients regarding specific polo shirt styles.

Rapid Prototyping: They offer very fast iteration on samples, which is crucial for custom designs.

Pros & Cons

Pros: Excellent for brands new to the fashion industry who need guidance.

Cons: As an intermediary, their pricing often includes a markup compared to going direct to polo shirt manufacturers. You may also face opacity regarding which physical factory is sewing your goods.

3. Zega Apparel

Location: Pakistan / USA

Zega continues to be a heavyweight in the “Full Package Production” (FPP) space. They are particularly strong in the streetwear sector and offer a wide range of customization options for custom polo shirts.

-

Website: zegaapparel.com

-

Main Products: Denim, Polos, Hoodies.

Manufacturing Capabilities

Fabric Variety: They have strong access to cotton and denim supply chains, making them one of the versatile apparel manufacturers.

Quality Assurance: They claim 3 separate quality control tests before shipping.

Verdict

Pros: Great for cotton-heavy designs.

Cons: The minimum order quantity of 200 pieces can be a high barrier for small test runs in the current agile market. Custom fabric dyeing can also extend lead times.

4. HONGYU Apparel

Location: Guangdong, China

Hongyu is a classic example of large-scale Chinese manufacturing. Located in the heart of the world’s garment district, they are one of the polo shirt manufacturers with massive capacity for bulk orders.

-

Website: hongyuapparel.com

-

Main Products: Streetwear, Large scale woven items.

Why Choose Hongyu?

Scale: Daily production up to 10,000 pieces. If you need bulk production, they are a powerhouse.

Workforce: Over 100 production personnel ensures lines keep moving efficiently.

Potential Drawbacks

Communication: Cultural and time zone barriers can slow down the detailing phase if you don’t have a comprehensive tech pack.

Logistics: Shipping costs on small orders can be prohibitive compared to local shirt manufacturers.

5. Thygesen Textile Group

Location: Vietnam (HQ: Denmark)

A veteran in the industry, Thygesen brings European management standards to Vietnamese manufacturing costs. They are excellent for brands looking for eco-friendly and sustainable options among polo manufacturers.

-

Website: thygesenapparel.com

-

Main Products: Knitted fabrics, Medical textiles, Polos.

Sustainability & Compliance

Certifications: High standards for labor and environmental certifications (SA8000, ISO).

Tech: Strong in knitting technology, producing high quality polo shirts with eco-friendly materials.

Pros & Cons

Pros: Highly compliant and ethical manufacturing services.

Cons: High entry barrier. They prefer working with established brands with high volume forecasts and are less flexible with custom designs compared to smaller, agile factories.

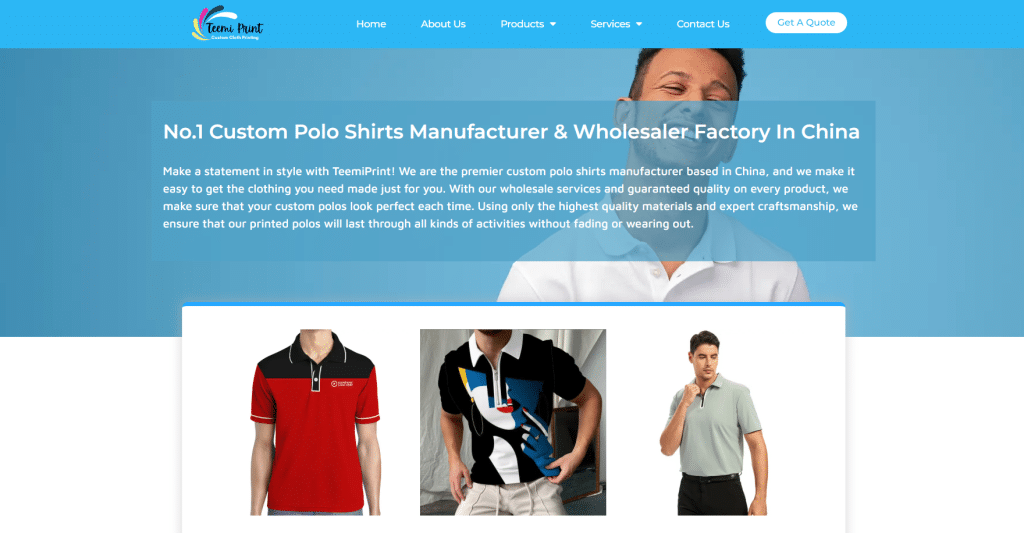

6. Teemiprint

Location: China

Teemiprint started as a printing specialist and evolved into garment making. If your polo shirt designs rely heavily on complex graphics or all-over sublimation, they are a strong contender among custom polo shirt manufacturers.

-

Website: https://teemiprint.com/

Specialization

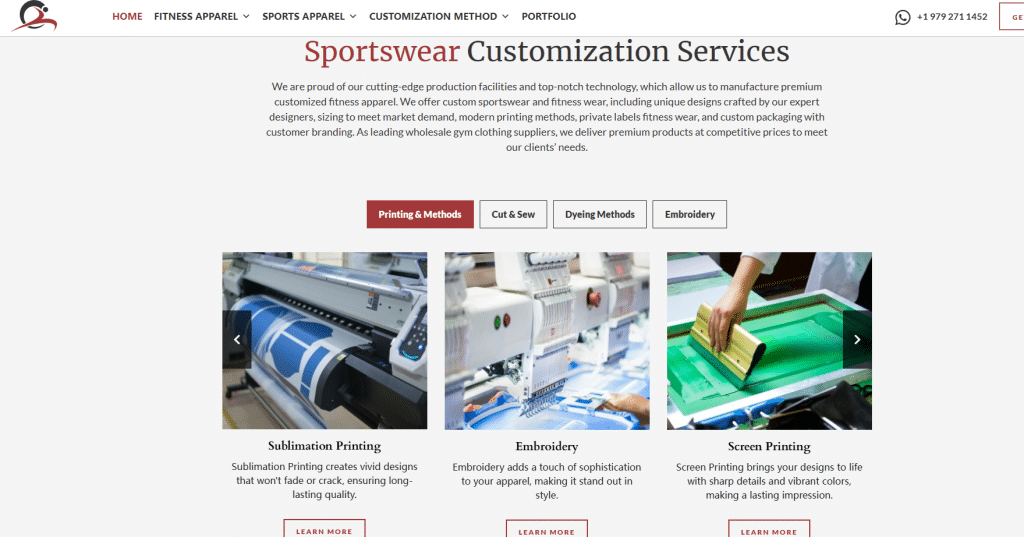

Printing Tech: Expert in DTG (Direct to Garment), screen printing, and Sublimation.

Focus: Unlike traditional Cut & Sew factories, their strength lies in the visual application.

Cons: The structural quality of the shirt chassis may be secondary to their printing focus.

Website: https://teemiprint.com/

7. Mega Sports Apparel

Location: USA (Manufacturing likely offshore)

Positioned as a partner for startups, they offer a wide range of sportswear products.

-

Website: https://megasportsapparel.com/

Startup Friendly?

Pros: Very startup-friendly with guidance on launching a brand in the apparel industry.

Cons: “Middleman” pricing structures apply, meaning you pay for the convenience rather than direct factory rates.

8. ZT Sportswear

Location: Pakistan

Specialists in breathable sportswear. Pakistan is a global hub for cotton-based textiles, making them a good choice for cotton-blend custom polo shirts.

-

Website: https://ztsportswear.com/

Material Focus

Pros: Good access to raw cotton materials; competitive prices.

Cons: Intellectual Property protection can sometimes be a concern in this region; ensure strict contracts when sharing your custom designs.

9. Bolun Apparel

Location: China

A reliable mid-sized factory offering one-stop services for clothing manufacturers.

-

Website: https://www.bolunapparel.com/

Overview

Pros: Good balance between price and quality for mid-market brands looking for custom clothing.

Cons: Limited R&D capabilities for high-tech performance fabrics compared to specialized polo shirt manufacturers.

10. Goodworth Sports

Location: Pakistan

A long-standing manufacturer focusing on team uniforms and sports apparel.

-

Website: https://goodworthsports.co/

Best Use Case

Pros: Very low cost for team uniform bulk orders.

Cons: May lack the “fashion-forward” fit required for modern lifestyle brands seeking high quality polo shirts.

Part 2: 2026 Polo Shirt Design Trends

To successfully sell custom polo shirts, you must understand what the market wants right now. As leading polo manufacturers, we see these trends dominating 2026:

1. The “Eco-Tech” Hybrid

Customers now demand sustainability without sacrificing performance. Polo shirt manufacturers are shifting towards Recycled Polyester (rPET) blended with organic cotton. This creates a high quality polo shirt that feels natural but wicks sweat.

2. Retro-Collar Revivals

The 90s are back. We are seeing a surge in requests for “Johnny Collars” (open placket without buttons) and contrasting retro piping. Custom designs that incorporate vintage aesthetics with modern fits are winning in the fashion industry.

3. Smart-Casual Versatility

The line between gym wear and office wear is gone. The 2026 polo must be structured enough for a Zoom call but stretchy enough for a golf swing. This requires advanced manufacturing processes using 4-way stretch pique fabrics.

Part 3: Engineering High Quality Polo Shirts (The Technical Details)

To sourcing managers and designers: You cannot order a “good polo” if you don’t know the specs. Here is what we look for at Maes Group when engineering a product.

1. Fabric Composition & Weight (GSM)

The “hand-feel” determines the sale.

-

The Classic Pique: Usually 100% Cotton or CVC (60% Cotton/40% Poly). Look for 200-220 GSM. It gives that structured, honeycomb texture associated with high quality polo shirts.

-

The Performance Polo: This is our specialty. We use 85% Polyester / 15% Spandex blends at 160-180 GSM.

-

Expert Tip: Ensure the fabric has a “wicking finish” (chemical treatment) or “wicking yarn” (physical structure). Wicking yarn lasts forever; chemical finishes wash out after 20 cycles.

-

2. The Collar Construction (The Anti-Roll)

A cheap polo has a collar that curls like bacon after one wash.

-

Flat Knit Collar: Ribbed texture. Must have spandex woven into the rib to prevent curling.

-

Self-Fabric Collar: Made of the same body fabric. Requires fusible interfacing (stiffener) inside to maintain shape.

3. Custom Embroidery vs. Screen Printing

-

Custom Embroidery: The gold standard for Polos. It offers high perceived value. Watch out for “puckering” (when the thread pulls the fabric). We use backing stabilizers to prevent this during the manufacturing process.

-

Screen Printing & Silicone Heat Transfer: Modern, sleek, and great for performance polos. Unlike custom embroidery, it doesn’t scratch the skin and is lighter weight.

Part 4: How to Vet a Trusted Polo Shirt Manufacturer

Not all factories are created equal. In the apparel industry, we categorize polo shirt manufacturers by scale and capability.

Factory Classification Guide

|

Class |

Size (People) |

Capabilities |

Best For… |

|---|---|---|---|

|

Class D |

3-10 |

Pure processing. No pattern making. |

Tailoring, modifications, ultra-micro batches. |

|

Class C |

10-30 |

Cut & Sew. Limited sourcing power. |

Small streetwear brands, simplistic custom designs. |

|

Class B |

30-100 |

Maes Group Level. R&D, Sourcing, QC. |

Brands needing high quality polo shirts, private label services, and export-grade QC. |

|

Class A |

100-1000+ |

Mass production lines. |

Giants like Nike/Adidas. Bulk orders usually 5,000+. |

The “Expert Filter” Questions

Don’t just ask “How much?” Ask these to prove you know what you are doing:

-

“What is your standard needle tolerance for seams? (ISO standard is usually +/- 1cm).”

-

“Do you relax the fabric before cutting to prevent shrinkage?” (Crucial for Spandex blends in custom clothing).

-

“Can you source Global Recycled Standard (GRS) certified polyester?”

Part 5: The Manufacturing Process (From Concept to Bulk)

Understanding the workflow helps you manage your timeline with clothing manufacturers.

Step 1: Sourcing & Lab Dips

(Duration: 7-10 Days)

We match your Pantone color exactly. This is critical for brand consistency in custom polo shirts.

Step 2: Pattern Grading

Digitizing your design for sizes XS through 3XL. Good apparel manufacturers ensure the fit remains consistent across all sizes.

Step 3: Fabric Relaxation

(Duration: 24 Hours)

We unroll the fabric and let it “rest” to release tension. Skipping this leads to twisted seams. This is a hallmark of high quality polo shirts.

Step 4: Cutting & Decoration

Using laser or automated cutters for precision. Custom embroidery or screen printing happens before sewing to ensure clean edges.

Step 5: Sewing & QC

The body, sleeves, and placket are assembled. Our quality control team checks trimming threads, steam ironing, and final measurements before packing.

Part 6: Where Are Polo Shirts Manufactured? (Sourcing Map)

-

China (The Tech Hub): The leader in complex fabrics and synthetics. If you need performance polos or intricate custom polo shirts, China (specifically Zhejiang and Guangdong) offers the best supply chain integration in 2026.

-

Vietnam: Excellent for large volume tariff-advantaged exports, but relies on China for raw fabric imports.

-

Bangladesh: The king of low-cost cotton basics. Great for promo-wear bulk orders, less so for high-end fashion.

-

Portugal/Turkey: The premium choice for European luxury cottons. High cost, high quality.

- India: India is also one of the main countries for Polo shirt production, known for its low-cost production and skilled labor force.

- United States: Although most of Polo Ralph Lauren’s products are manufactured overseas, the company also has some production in the United States, such as the uniforms made for the U.S. Olympic team in 2018.

Part 7: How to Collaborate With Us (Expert Tips)

As a Technical Director, I see many startups fail because they don’t know how to talk to a shirt manufacturer. Here is how to get priority treatment:

1. Be Clear on “Full Package” vs. “CMT”

-

CMT (Cut, Make, Trim): You buy the fabric and send it to us. We just sew. (Risky for beginners).

-

FPP (Full Package Production): We handle everything—fabric sourcing, trims, buttons, tags, and packaging. Recommended for most clients looking for private label solutions.

2. The Golden Rule of Communication

When you contact polo shirt manufacturers, answer these 4 questions immediately:

-

Target Quantity: (e.g., “150 pieces per color”). This helps us determine if you meet the minimum order quantity.

-

Fabric Preference: (e.g., “I need a heavy cotton pique” or “I need a dry-fit blend”).

-

Tech Pack Status: (e.g., “I have a tech pack” or “I only have photos”).

-

Target Market: (e.g., “High-end golf apparel”).

Pro Tip: Factories ignore vague emails like “How much for a polo?” Be specific to be taken seriously.

Conclusion: Finding Your Trusted Partner

The market for fashion polo shirts and activewear is crowded. To stand out, you need product quality that rivals the top athletic brands, but at a price point that allows you to scale.

Whether you are an established brand looking for bulk production or a startup exploring polo shirt styles, the manufacturer you choose is your business partner, not just a vendor. You need a partner who understands custom designs, offers private label options, and guarantees quality control.

Ready to engineer your next bestseller?

At Maes Group, we combine nearly three decades of technical expertise with modern fashion sensibilities. We don’t just sew; we solve problems.

Contact Our Technical Team Today to discuss your project, request fabric swatches, or get a quote on your 2026 custom polo shirts.

What is the difference between a Seamless and Cut & Sew Polo?

Seamless knitting creates a tube-like garment (good for compression gear). Cut & Sew (what we do) involves cutting fabric panels and stitching them. Cut & Sew is required for traditional Polo structures, sharp collars, and tailored fits found in high quality polo shirts.

What is the best printing method for Polyester Polos?

Sublimation or Silicone Heat Transfer. Avoid standard screen printing on high-stretch poly if the ink isn’t elastic, as it will crack when stretched.

Do you offer sustainable fabrics?

Yes, as responsible clothing manufacturers, we offer Recycled Polyester (rPET) derived from plastic bottles and organic cotton blends.

What is your Minimum Order Quantity (MOQ)?

We are one of the few polo shirt manufacturers that support startups with an MOQ of just 100 pieces per color/style, while also handling large bulk orders.