A complete set of the process flow of customized sportswear is the guarantee to make high-quality custom sportswear. China has many fitness apparel manufactures and factories to make customized sportswear. The specific process to customize your own sportswear from China is as follows:

- Design style and select fabrics.

- Produces patterns through the computer.

- Sewing.

- Audit and improvement.

- Final determination [fabrics, size, color]

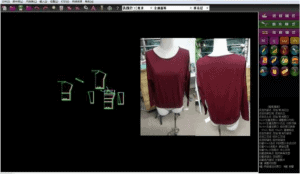

Step 1: pattern making

If you want to customize your own sportswear, a patter making must be required. If you have sportswear sample, you can directly provide us with sample. If you want to make your favorite sportswear style, and there is no sample clothes, you can also send us the pictures directly. Our professional pattern making department can do pattern making according to the pictures you provide.

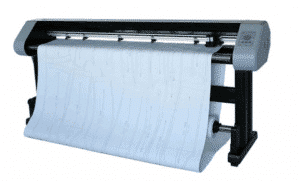

Step 2: computer clothing grading and clipping

Note: Before the large cargo is clipped, the worker must check the marker frame carefully against the sample sportswear, and check whether there is wrong or missing piece when arranging the marker. You should pay attention to the fact that a large quantity of goods on the planting bed can not be changed in design and size midway after clipped. Because the clipped small pieces can’t be changed any more, once you want to change, it will cause great loss and increase the cost.

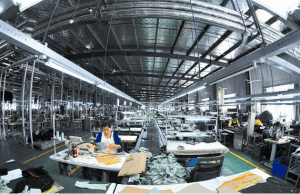

Step 3: sewing

Now more than 40% of the sportswear factories have selected the computer flat car equipment, and our factory is no exception. However, there are still some manufacturers with weak strength who still choose ordinary flat cars.

Comparison between computer flat car and ordinary flat car to customize your own sportswear:

Computer flat car: semi automatic setting, the stitching line is relatively flat and even, and can automatically reverse the needle and cut the thread. The finish garment is clean and has no excess thread. It is easy to operate and greatly improves the production output.

Ordinary flat car: it is set manually, and the line is determined by workers’ gestures, which is difficult to control. There are more clothing thread ends made of ordinary flat car, and the production capacity is relatively low.

Sportswear production is divided into flow line production and whole piece production to Customize Your Own Sportswear.

Flowline production: it is suitable for customers who have a large number of orders and require the whole batch to be shipped. The quality control of the whole batch of goods is better.

Whole piece production: it is suitable for customers with small orders. The finished products can be produced quickly by arranging the parking space in one quantity. According to the customer’s demand, color and size can meet the customers’ urgent needs. This production arrangement is more suitable for the existing e-commerce Taobao customers, and the shipment is more flexible and changeable.

Step 4: special technique production

As for this step to Customize Your Own Sportswear, many customers who have not participated in the production of sportswear have a vague concept of special technique. Due to the more and more attention paid to the technique of sportswear, many special techniques have been added to the production process of sportswear. Today’s Taobao brand split silk, which has strong design elements, is a very representative example. The special process mainly includes printing, hot stamping, embroidery, washing water, flocking, fixing beads, jujube, folding, special machine, nail button, etc.

There are many types of stapling such as flat eye button, mushroom button and so on, the machines used are different. A piece of finish clothes is not finished by using a computer flat car. It also includes the production of these special techniques just introduced. Different styles use different techniques. The production time varies with the technique. Here are some special craft machines to Customize Your Own Sportswear.

Step 5: inspection, ironing, packaging, shipping

This is the last step to Customize Your Own Sportswear, and it is also a very important step. Every finished product in our factory needs to be inspected by the quality inspector one by one and can be delivered only after it is qualified. Ironing is the most important aspect. Different sportswear has different ironing methods. Due to different fabrics, the temperature used for ironing is also different.