There are 5 common types of calendering machine in China’s textile industry, including mirror surface calender, oil surface calender, film calender, seven-roll calender and embossing machine.

What Is Calendering?

Calendering is a process of fabric finishing. It is a finishing process that uses the physical plasticity of the fiber under high pressure or high temperature conditions to flatten or roll out patterns on the surface of the fabric to enhance the gloss of the fabric.

Depending on the roll surface material, rolling pressure, temperature, different soft and hard roll combinations and cloth threading methods, different calendering effects can be obtained. The common calendering equipment used in the finishing of garment fabrics in Jiangsu and Zhejiang can be summarized as mirror surface calender, oil surface calender, film calender, seven-roll calender and embossing machine.

Calendering Machine: Mirror Surface Calender

The upper rod is a metal rod with highly polished surface, which is also a heating roller. The middle rod is nylon rod, and the lower rod is metal rod, which mainly plays the role of supporting rod. In production, the cloth passes through the upper rod (heating roller) and the middle rod (nylon rod). Under the pressure state, the heating roller and nylon rod form the rolling point, and the cloth passes through the rolling point to achieve the calendering effect. There are also two mirror calenders and controllable medium high mirror calenders on the market, which are similar in nature!

Process: temperature from cold pressing to 160 ℃, speed 70 m / min, pressure 8-10 kg.

Usage: it is mainly used for the fabric that needs to be calendered with general luster, improving the handle (the handle will become soft and smooth after calendering), the flatness of the calendered surface, removing the paste on the surface of the dyed and finished fabric (the surface looks like white watermark), changing the color (the color will become lighter after calendering), and the previous process of coating finishing (the coating after calendering can increase the water pressure resistance of the fabric, and the glue surface will be smoother) For example, 380t Nisi (no guts down proof), which is popular in recent years, is a kind of lightweight down jacket fabric.

Calendering Machine: Oil Surface Calender

The difference between oil surface calender and mirror surface calender is that the lower rod of oil surface is rubber rod (soft rod), while the mirror surface is nylon rod (hard rod). The working principle is basically the same!

Process: temperature 160-220 ℃, pressure 6-8kg, speed 70m / min

Usage: fabric calendering finishing requires super bright luster, or slightly bright and soft luster, and oil finish is also commonly used for those requiring less color change after calendering finishing (the color change of fabric after mirror rolling is larger).

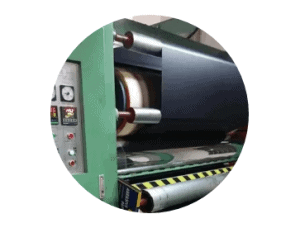

Calendering Machine: Film Calender

The middle is metal rod (heating roller) and the top and bottom is nylon rod (imported nylon is better). When working, the cloth passes through the lower rod and heating roller, and then between the heating roller and the upper rod, so as to form two rolling points, which is equivalent to the fabric being rolled twice. Also has the intermediate metal rod surface to pass the layer ceramic rod the skin Film Calender, after the rolling luster is more matte, has the fog surface effect!

Process: temperature 120-160 ℃, pressure 8-10kg, 40m / min

Usage: the fabric is required to be glossy and matte, soft and thick, waxy and skin like, and has the effect of leather film, such as Multi-f polyester taff leather film calendering finishing.

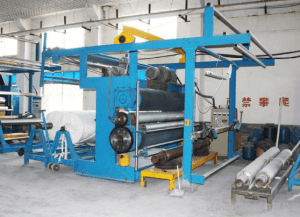

Calendering Machine: Seven-roll Calender

It is composed of two heating rollers, three cotton sticks and two upper and lower metal idlers. When working, the cloth is bypassed between the rollers to form five rolling points, so as to achieve the effect of repeated calendering. Similar to the seven roll machine, there are five roll calender and six roll machine which changes the bottom two rolls of the seven roll machine into a nylon rod. The working principle is basically the same!

Process: temperature 110-140 ℃, pressure 4-8kg, speed 60m / min

Usage: mainly used for down proof finishing of down jacket liner, such as 290t polyester taffeta liner.

Calendering Machine: Embossing Machine

Embossing machine is mainly used to emboss, bubble, wrinkle and mark on all kinds of fabrics. It can also emboss mark on non-woven fabric, coating, human leather, paper and aluminum plate to imitate leather pattern and various patterns.

Ultrasonic embossing machine, also known as ultrasonic lace machine, is an efficient sewing and embossing equipment. It is mainly used for seam edge, welding, cutting and embossing of synthetic fiber cloth. The processed products have the characteristics of good water tightness, high production efficiency, no needlework accessories, smooth cutting surface, no burr and good handle. Widely used in fitness clothing, toys, food, environmental protection non-woven bags, masks (cup masks, flat masks, three-dimensional masks, etc.) and other industries.