Introduction: Why Recycled Plastic Activewear is the 2026 Engineering Standard

In the 2026 manufacturing landscape, sustainability is no longer a marketing advantage—it is a baseline requirement for market entry and risk mitigation. For brand owners and procurement managers, sourcing sportswear made from recycled plastic is a critical strategic decision, driven by stringent global regulations and sophisticated consumer expectations. Traditional sportswear materials like polyester, spandex, and nylon are not biodegradable and heavily contribute to petroleum use. While recycled polyester (rPET) is the focus of this guide, the landscape also includes innovative plant-based materials like Tencel™, signaling a broader industry shift away from virgin synthetics.

The full implementation of laws like the EU’s Ecodesign for Sustainable Products Regulation (ESPR) means your supply chain must guarantee compliance. The question is no longer if recycled materials can compete with virgin polyester in the high-performance sector, but how to engineer them for maximum quality and brand value.

By 2026 standards, modern rPET (Recycled Polyethylene Terephthalate) technology has surpassed older generations in both durability and hand-feel. As a high-end Cut & Sew manufacturer, Maes Group combines over 20 years of textile engineering with GRS-certified sustainable practices. This guide strips away the marketing fluff to deliver the technical realities of activewear made from recycled plastic, helping you secure a future-proof supply chain.

An Engineer’s View: Key Manufacturing Decisions for Recycled Sportswear

Creating premium workout leggings or technical tops from recycled plastic bottles goes beyond simply choosing a green fabric. True quality is determined by engineering decisions made before the first pattern is ever cut. As a specialist in Cut & Sew manufacturing, here is where we focus our expertise:

- Fabric Selection & Specification: We go beyond just “rPET”. We analyze GSM (Grams per Square Meter), yarn denier, and finishing (e.g., wicking, anti-odor) to match the fabric to your product’s end-use, whether it’s for high-compression leggings or a lightweight running tee.

- Stitch & Seam Construction: This is a critical differentiator. For high-stretch garments, a 4-needle 6-thread flatlock stitch provides superior durability and comfort against the skin, preventing chafing. This is a hallmark of high-end activewear that seamless production cannot replicate.

- Thread Integrity: We advocate for using recycled polyester thread (from brands like A&E) to create a “100% recycled” product, a powerful and verifiable claim that adds immense brand value.

⭐ Expert Tip for Startups

To reduce sampling costs on your tech pack, specify that initial fit samples (Proto 1, Proto 2) can use our in-stock, stock-color rPET fabric. Only request and pay for a custom Pantone lab dip once the fit and construction are fully approved. This single step can save you hundreds in dye setup fees per iteration and accelerate your development timeline.

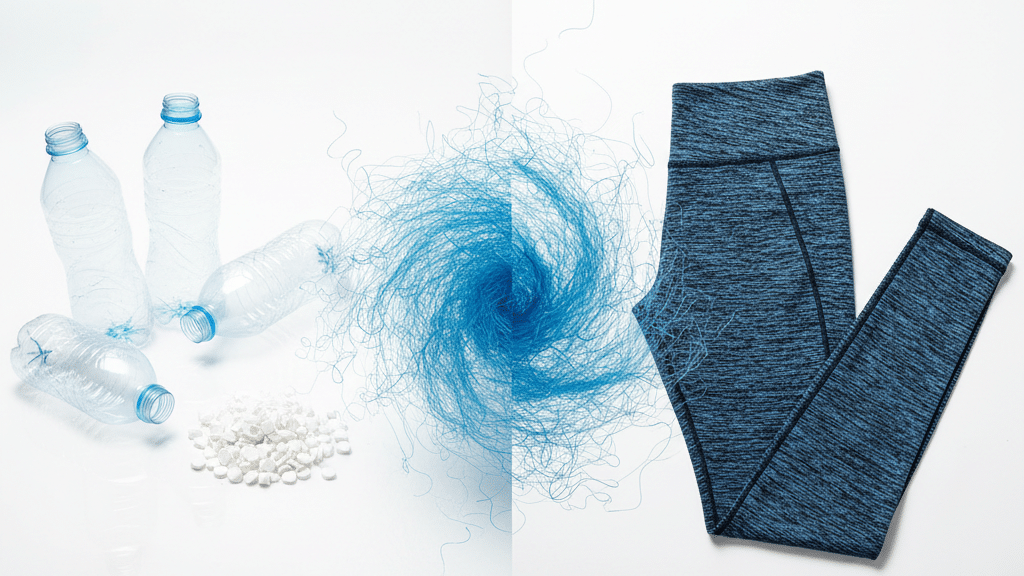

The Engineering Behind the Fabric: From Bottle to High-Performance Fiber

Contrary to the outdated misconception that recycled plastic activewear is “rough” or “fragile,” modern 2026-era rPET (Recycled Polyethylene Terephthalate) rivals—and often exceeds—virgin polyester in technical specs. RPET fabrics, made from recycled plastic bottles, use significantly less water, CO2, and energy compared to traditional materials, making them a more sustainable choice. This transformation is the core of ‘closing the loop’ in modern sportswear, turning potential textile waste into a high-value, engineered material.

The transformation from post-consumer waste to premium textile involves precise chemical and mechanical engineering:

- Collection & Sorting: Used plastic bottles are gathered from recycling streams. The place where bottles are sourced is important, with many coming from coastal areas and urban waste streams. Minimizing the distance in sourcing helps ensure ethical and sustainable practices throughout the supply chain.

- Cleaning & Shredding: Bottles are washed and shredded into small flakes.

- Melting & Spinning: The clean flakes are melted and extruded into recycled polyester yarn (rPET).

- Weaving & Dyeing: The yarn is woven or knitted into fabric, then dyed using eco-friendly techniques.

- Cut & Sew: Fabrics are transformed into custom activewear, from t-shirts, pants, workout leggings, supportive sports bras, and tops, to leggings—many featuring practical pockets for convenience and versatility. These products are manufactured ethically, with transparency and fair labor practices, ensuring responsible production for both people and planet.

It’s important to acknowledge that microplastics are released when washing any polyester. We recommend using wash bags (like Guppyfriend) as a best practice, a valuable educational point for your customers.

Myth-Busting: Is Recycled Sportswear “Dirty” or Low Quality?

Let’s address the most common procurement concern: “Is it hygienic and durable?”

The short answer: It is clinically clean and engineered to outperform.

Before becoming clothing, the plastic passes through a multi-step, high-temperature purification process. The resulting rPET fabric is not only OEKO-TEX® Standard 100 certified (free from harmful substances) but is proven to be durable and long-lasting.

- Proven Performance: Market leaders in eco-friendly athletic clothing have proven that modern rPET holds color vibrancy (Colorfastness to Washing Grade 4.0+) and elasticity just as well as, or better than, traditional fabrics after 50+ wash cycles.

- Superior Resilience: Many athletes find that next-generation recycled fibers outperform virgin synthetics in elasticity and shape retention, making them a top choice for high-impact outdoor and athletic clothing.

Leading brands like Patagonia pioneered this technology, setting the benchmark. We build upon that legacy with advanced Cut & Sew techniques to ensure every garment is ready for elite performance.

(Caption: We can customize heat-transfer tags displaying your brand’s recycled bottle count. This is a key feature for marketing sportswear made from recycled plastic.)

Data Analysis: Recycled Polyester (rPET) vs. Virgin Polyester

For a Technical Director or procurement manager, the numbers speak louder than words. Our 2026 lab tests show that sportswear made from recycled plastic offers zero performance trade-offs.

| Performance Metric | Recycled Polyester (rPET) | Virgin Polyester | Traditional Cotton |

|---|---|---|---|

| Tensile Strength | High (5.0+ g/d) | High | Low |

| Moisture Wicking | Excellent (Hydrophobic base) | Excellent | Poor (Absorbs moisture) |

| Abrasion Resistance | High (Grade 4-5) | High (Grade 4-5) | Low |

| Color Fastness | Excellent | Excellent | Moderate |

| Carbon Footprint | ~40-50% Lower | High | High (Water usage) |

| Hand-Feel | Soft (Advanced Finishing) | Soft | Very Soft |

Conclusion: The data confirms that rPET delivers identical technical performance while offering a massive reduction in environmental impact—a powerful, data-backed selling point for your eco-conscious demographics.

Strategic Imperatives for 2026: Why rPET is Non-Negotiable

Switching your production to recycled plastic activewear is now a matter of strategic necessity.

- Risk Mitigation: Ensure compliance with 2026 global trade standards regarding recycled content percentages, avoiding costly plastic taxes and import restrictions.

- Market Access & Loyalty: US and EU consumers now demand transparency as a non-negotiable part of their purchasing decision. Sustainability is the price of entry.

- Tangible CSR & Circularity: Using rPET allows for verifiable impact reports (e.g., “This collection diverted 500kg of ocean-bound plastic”). This also opens the door for brand-led take-back programs, like those pioneered by brands such as Girlfriend Collective, further enhancing consumer loyalty and building a truly circular brand story.

Industry leaders are already making the switch: Waste2Wear manufactures sportswear from 100% post-consumer recycled plastic bottles. Adidas’ Primeblue collection is made with recycled polyester sourced from ocean plastic. Nike utilizes recycled polyester from plastic bottles and employs its “Grind” campaign to upcycle materials into high-end apparel.

The business case for rPET is clear—brands can save money by reducing raw material costs and avoiding penalties, while also increasing consumer trust through transparent sourcing and responsible practices.

OEM & Private Label Solutions: Your GRS-Certified Production Partner

At Maes Group, we provide a turnkey engineering solution for brands scaling in the 2026 market. At Maes Group, we provide a turnkey engineering solution for brands scaling in the 2026 market. Explore our full capabilities at our Sustainable Activewear Factory page.

1. The “Tech-Pack to Product” Process

- Step 1: Consultation & Fabric Selection: Choose from our 2026 library of certified recycled polyester sportswear fabrics (Interlock, Jersey, Mesh, etc.).

- Step 2: Prototyping (7-10 Days): We create a “Pre-Production Sample” (PPS) with your branding. All sublimation, screen printing, and heat transfers are handled in-house for quality control.

- Step 3: GRS Certified Production: Once approved, bulk production begins under strict QC checkpoints. We are fully equipped to manage the GRS Transaction Certificate (TC) process for your order.

2. Flexible MOQs for Agile Brands

We understand that inventory efficiency is key in 2026. That’s why we offer:

- Low MOQ: Starting at 100 pieces per style/color for custom orders.

- Fast Turnaround: 20-30 days for bulk production.

3. Customization Depth

- Custom Tags & Packaging: Fully biodegradable polybags and recycled hangtags to match your eco-story.

- Pantone Matching: We match your brand colors exactly using eco-friendly, azo-free dyes.

What Our Customers Say: Real Feedback from Our Partners

At Maes Group, we don’t just manufacture clothes; we build brands. But don’t just take our word for it. Here is what real gym owners, boutique brands, and purchasing managers are saying about their recent orders of recycled plastic activewear.

1. “Perfect As Always” – Consistent Quality for Repeat Orders

Why this matters: Consistency is the hardest thing to find in a manufacturer. This long-term partner highlights that our quality isn’t a one-time luck; it’s “perfect as always.” Notice the neat packaging—ready for retail immediately upon arrival.

2. “Received Everything Today” – Reliable Logistics

Why this matters: In the fashion industry, a late shipment equals lost sales. We pride ourselves on transparent communication and on-time delivery, whether via sea freight or express air. When we say it’s shipped, it’s shipped.

3. “Super Excited” – Exceeding Expectations

Why this matters: There is no better feeling than unboxing a sample that looks better than the design file. We work tirelessly on the “pre-production” phase to ensure that when your bulk order arrives, your reaction is just like this: “You are amazing!”

Ready to Future-Proof Your Activewear Line?

Don’t let the technical complexity of sustainable sourcing slow you down. Partner with a manufacturer who speaks your language—from “Tech Packs” to “Landed Cost.”

Start your sustainable collection with us today. Let’s discuss how we can integrate sportswear made from recycled plastic into your 2026 catalog with premium quality and competitive pricing.

Frequently Asked Questions (B2B)

Q: Do you provide GRS certificates for the fabric?

A: Yes. We provide the Transaction Certificate (TC) upon request for bulk orders, proving the origin of the recycled material. This is crucial for verifying claims under 2026 anti-greenwashing laws.

Q: How does the cost compare to virgin polyester in 2026?

A: The raw rPET fiber typically has a 10-20% cost premium over virgin polyester. However, this is frequently offset by avoiding emerging plastic taxes and by the higher retail value and demand for verifiably sustainable products. We help you manage total cost through efficient Cut & Sew production and optimized material sourcing.

Q: Can we do full-body sublimation on recycled fabric?

A: Absolutely. Sportswear made from recycled plastic is polyester-based, which is the perfect medium for sublimation printing. The colors appear vivid and do not fade or crack.

Q: What is the “bottle count” for marketing purposes?

A: Generally, it takes about 8 to 12 plastic bottles (500ml size) to produce one adult performance t-shirt. We can help calculate total impact stats for your marketing campaign